Test Lab

Tensile Tester

You can rest assured that your order will be manufactured and tested to exacting standards. Within Spectra’s in-house test lab, we run thorough quality inspections to ensure your products meet your exact mechanical specifications.

Our tensile tester provides ATSM compliant readings for the ultimate tensile strength, yield tensile strength and elongation %. Additional specifications include:

- Graphic display of Ultimate tensile strength and Yield strength.

- 50KN / 11,250 LBF / 5,100 KGF Capacity

- 20 inch/min, 508mm/min Speeds

- Frame stiffness = 800 klbf/in

- Total vertical test space = 18 inches

- Crosshead guidance system (maximum lateral motion 0.010" over full crosshead travel)

- Interchangeable, electronic load cell-weighing system

- Anti-backlash system

- Adjustable overload stop

Optical Measuring Device with Full Featured Measurement Software

In order to deliver on our promise of quality, we continue to invest in the latest technology for quality testing. Our optical measuring device allows us to conduct a detailed analysis of what is produced compared digitally with the customer approved drawings. It then provides detailed reports on a number of different levels including:

- Electronic Report Generation for Material Certs that are logged indefinitely

- GD&T Analysis including datum structures, tolerancing and material condition

- Replaces an optical comparitor

- Full field of view image processing with Software tools for arc, circle, line, edge tracing, minimum point, maximum point, average point, centroid, etc.

- Software solves composite XY, YZ and XZ profile fitting

- Identifies Trouble Spots, Trends, and Potential Assembly problems

- Creates a Perpetual Library of Profile Snapshots to track Trends and Alterations

- Reverse Engineers a sample in seconds

- 12”x12”x10” XYZ Travel

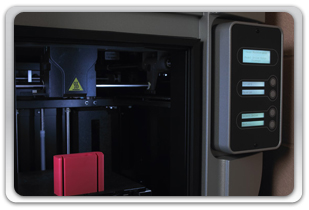

3D Prototyping

Our 3D prototype printer allows us to create a mockup within hours from CAD data you provide, on site, saving you time and money when designing new products or changing existing ones.

This state of the art system uses a dual tipped extrusion head that deposits liquefied ABS starting from the bottom up, layer by layer. Your prototype will allow us to conduct fit/form/function and compatibility analyses.

Standard ABS colours include white, red, blue, green, grey, yellow and custom. We can design multiple concepts with a full-scale product mockup within a 10”x10”x12” build envelope.

Coordinate Measuring Machine (CMM)

This device will measure a physical part in all 3 dimensions by touching it ever so gently with a very sensitive probe. The probe is mounted to a gantry and moves it all over the part, verifying the part is within dimensional tolerance.

Additional specifications include:

- 18” x 20” x 14” (XYZ) Measuring Capacity

- Renishaw PH50 motorized articulating probe head with ruby stylus.

- Active temperature compensation systems for use in non-lab environment.

- 20µin Resolution

- X-axis = 175 µin, Y-axis = 165 µin, Z-axis = 165 µin Linear Accuracy

- 68 +/- 2 °F Temp range

- 120µin Repeatability

- 60 points/minute throughput

High-Resolution Colour Camera with 287x Zoom

Note: We willtake a close up picture of the grain analysis we have done and use this for this picture

At Spectra, we have the in-house capability to conduct detailed metallurgical grain structure analysis with our high-resolution zoom camera. This camera has 287x Zoom capacity and other amazing features:

- 3 Different light sources for Surface Defect Analysis

- 12:1 Auto-Calibrating Zoom Lens

- All White 8 Sector/Ring LED lighting – High performance back light

- Amazing 0.00002” (0.5 micron) Resolution Scales

- Digital Storage of Images